In order to improve ground clearance I am trying to fit the front anti roll bar above the chassis leg,

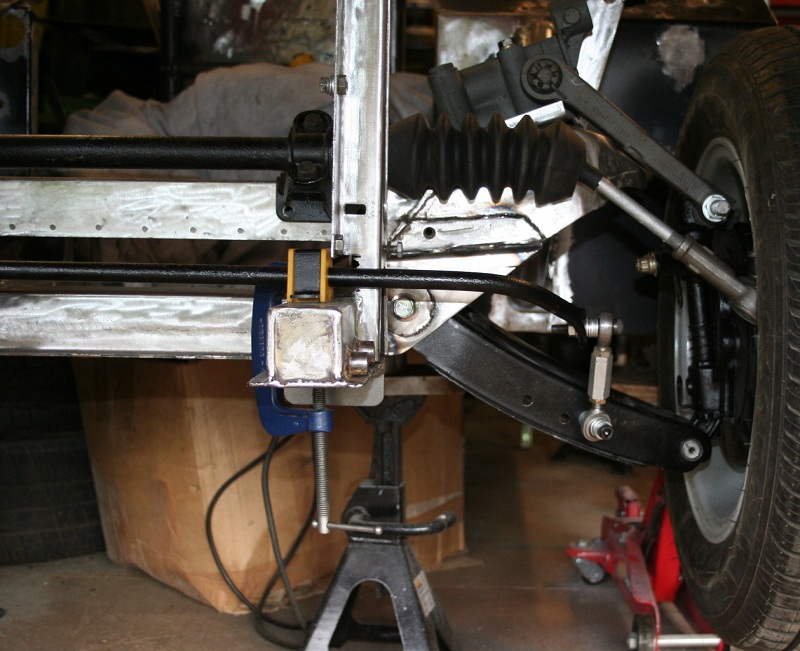

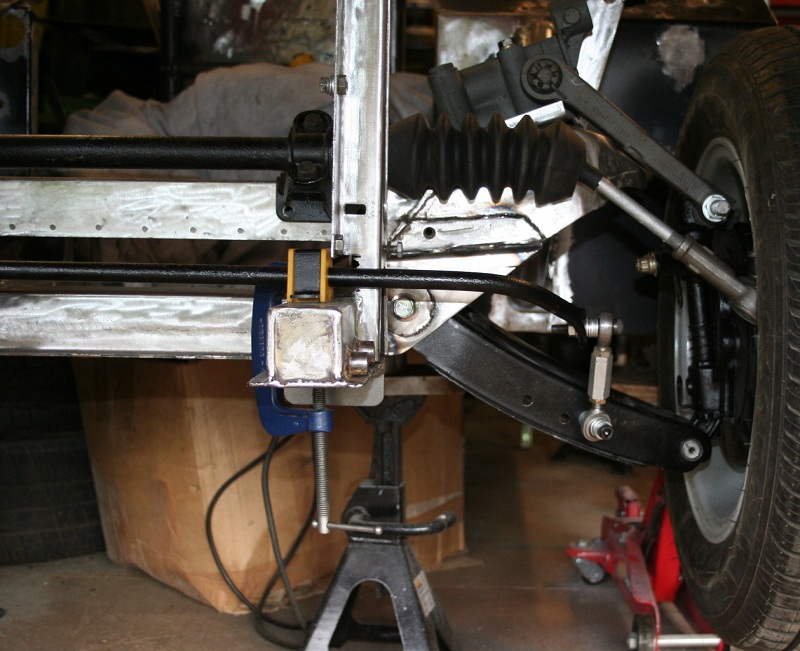

The first look see:

The LF suspension and road wheel is fitted to check for clashes and to move the suspension from full droop, through ride height and in to full bump.

One big problem when fitting an anti roll bar in a custom position is the drop links necking out and creating side loads or other undesirable affects

I plan on fitting an adjustable (spherical) drop link on one side and a std drop link on the other, at the moment this set up is good at full droop and ride height but starts to load the anti roll bar laterally at full bump so I need to experiment further with drop link length and angles to make sure there are no side loads applied throughout full suspension travel.

Started to seal and etch prime the bits I have already done as things need to be tidied up, I have put the thinnest 'smear' of seam sealer to the welded joints. Initially I brushed the sealer in place but I ended up applying it like you would if you were sealing a bath.

I preferred how it looked before the seam sealer better but realise it had to be done

Can you tell what it is yet?

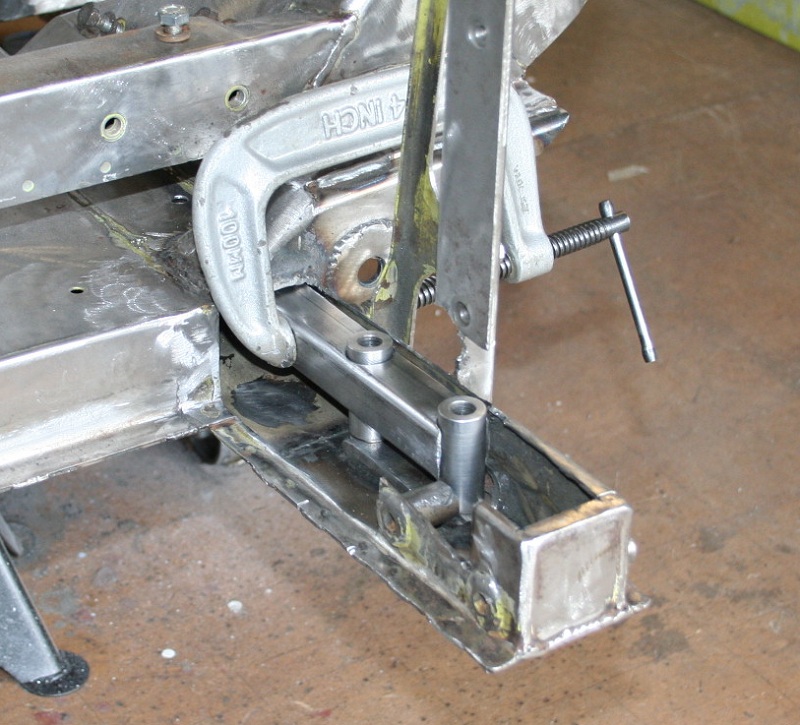

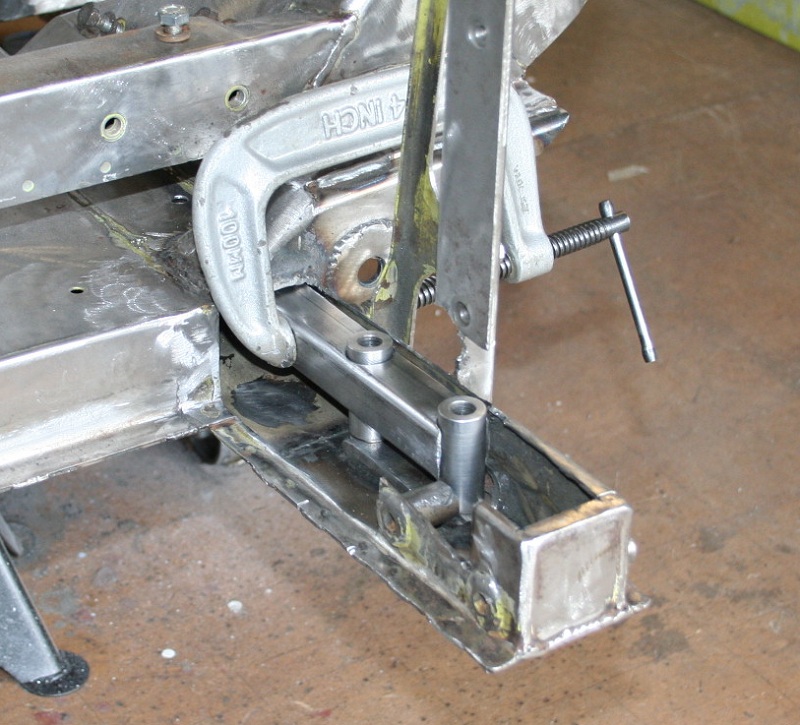

The work I have done previously on the front anti roll bar mounts was OK in terms of tidying the underside up but I want to tie the mounts better to the front crossmember.

The 25mm box section fits inside the main chassis leg and is tied to the chassis legs and the lateral crossmember

The two turned bushes will be welded to the box section and the existing threaded lower FARB mounting plate.

Before everything was welded the front panel was fitted and two chassis legs were aligned and G clamped to minimise how much it moves when welded

Tied to the tops of the chassis legs

Tidied up a bit

Plug / rose welds to the crossmember to the internal box section, these were 10mm holes to ensure the weld gets properly penetrated into the box section

Just needs to have some internal plating and the external surface reinstated

These mounts allow me to fit the FARB above the chassis leg as previously shown but the original mounts still exist below so can be put back to standard but with improved location.

The difference it has made to the chassis leg stiffness ahead of the crossmember is really suprising considering the original chassis leg sections haven't yet been put back.

Also finished the LF mudguard / inner arch ready to weld in place, triangular openings again closed off.

Replaced the outer skin of the front chassis leg after I had added a few more bits of internal stiffening, basically connecting the 25mm box to the lower skin of the original chassis leg.

Welded an linished in place:

Just the two holes give the game away as all else in now hidden again.

I also have started getting the various fasteners I will need together, I don't like using Nylocs, especially as they still seem to be regularly used near heat sources such as brakes and suspension parts.

I am using K nuts which are aerospace locking nuts, they also have the advantage that they are much smaller in size and for things such as the track rod ends which tend to touch alloy wheels gives a useful couple of mm extra space.

Cheers

Cheers