garage, one of the parts for the radiator brackets needs

to be twisted so it had to be heated first.

I got the blow tourch out, it is one of those you put a

canister like thing into it and screw tight. there is a

thing that both punctures the canistr and is supposed to

seal the connection.

Only it didn't seal properly with me at first, as I

found out with a lit match!! I singed my fringe!!!

As the blow torch surrounded it's self with yellow flame

I tossed it onto the grass and promptly poured the contents

of the watering can over it putting out the flames!!

I left it for a good 20 min to make sure it had gone out

and cooled down before going anywhere near it.

I then lit a match and made sure it wasn't leaking,

before turning it on.

I heated the bar for a good 10+ minutes before using the

large G clamp to twist the bar 90 bdegrees to the correct

turn.

I managed to get the grinder out for about an hour this

afternoon before it started raining.

one bit of box section.

Two mirrored parts.

A little grinding and then the rain came down. The brackets

still need a little fine tuning with the grinder to fit properly,

and it needs the rubber padding.

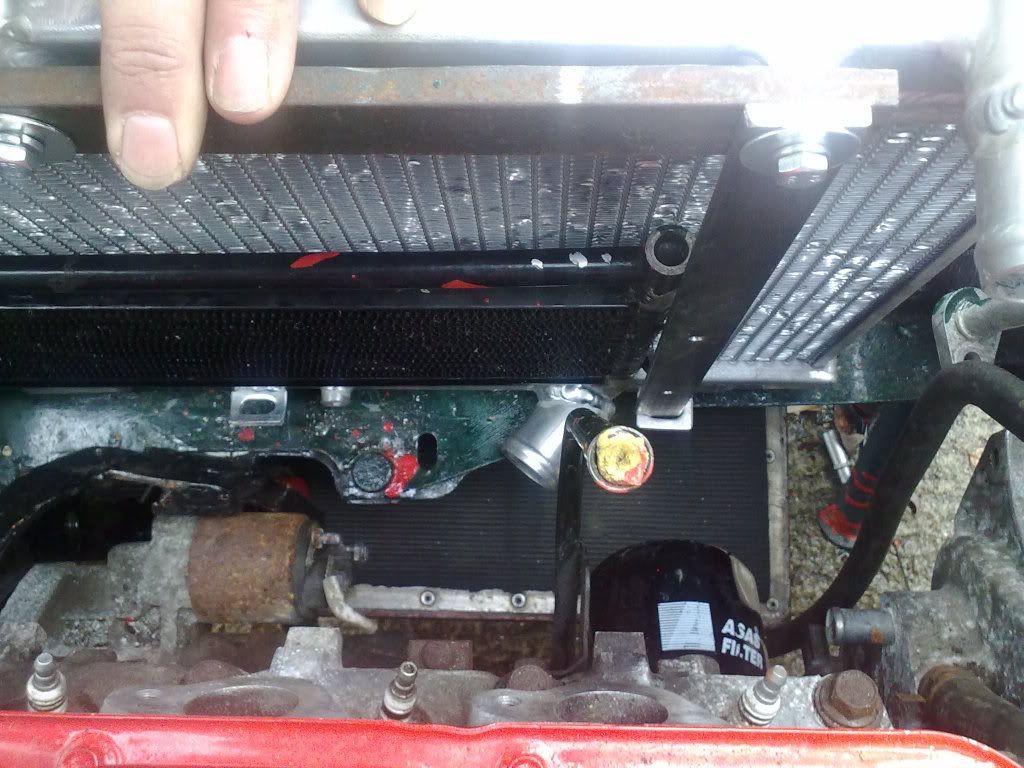

But here is what it looks like at the moment.

The top mounting bracket is started but there are still

parts for the upper fixing bracket to to make.

Depending on the weather depends on what can be done!