Series 3 Landie FFR

Posted: Wed Apr 15, 2015 2:46 pm

The other vehicle in the fleet beside the UAZ is a 1973 Series 4 landrover - ex-military 109" DDR with all the joys of a 24v high amp electrical system....

However - the current issue is nothing to do with that. Last October i was headed down to Hampshire to collect a Sankey trailer for a friend and as I approached J9 of the M3 with everything running sweetly I felt the dreaded clunking wihch told of a puncture. Pulled over and swapped the wheel over then went to pull away. Engine started fine but suddenly I had no power. I crawled up the J9 slip road and then took 4 attempts to get through the lights, picking up a friendly police escort in the process . Sortly thereafter it died altogether and I had to get a ride home with the RAC - two rides actually as their hitch would not fit the Sankey tow ring so we had the landie on one truck and the Sankey on the other.

. Sortly thereafter it died altogether and I had to get a ride home with the RAC - two rides actually as their hitch would not fit the Sankey tow ring so we had the landie on one truck and the Sankey on the other.

Once home I ran a compression check and the source of the problem was immediate:

Cyl #1 - 70 psi

Cyl #2 - 70 psi

Cyl #3 - 0 psi

Cyl #4 - 0 psi

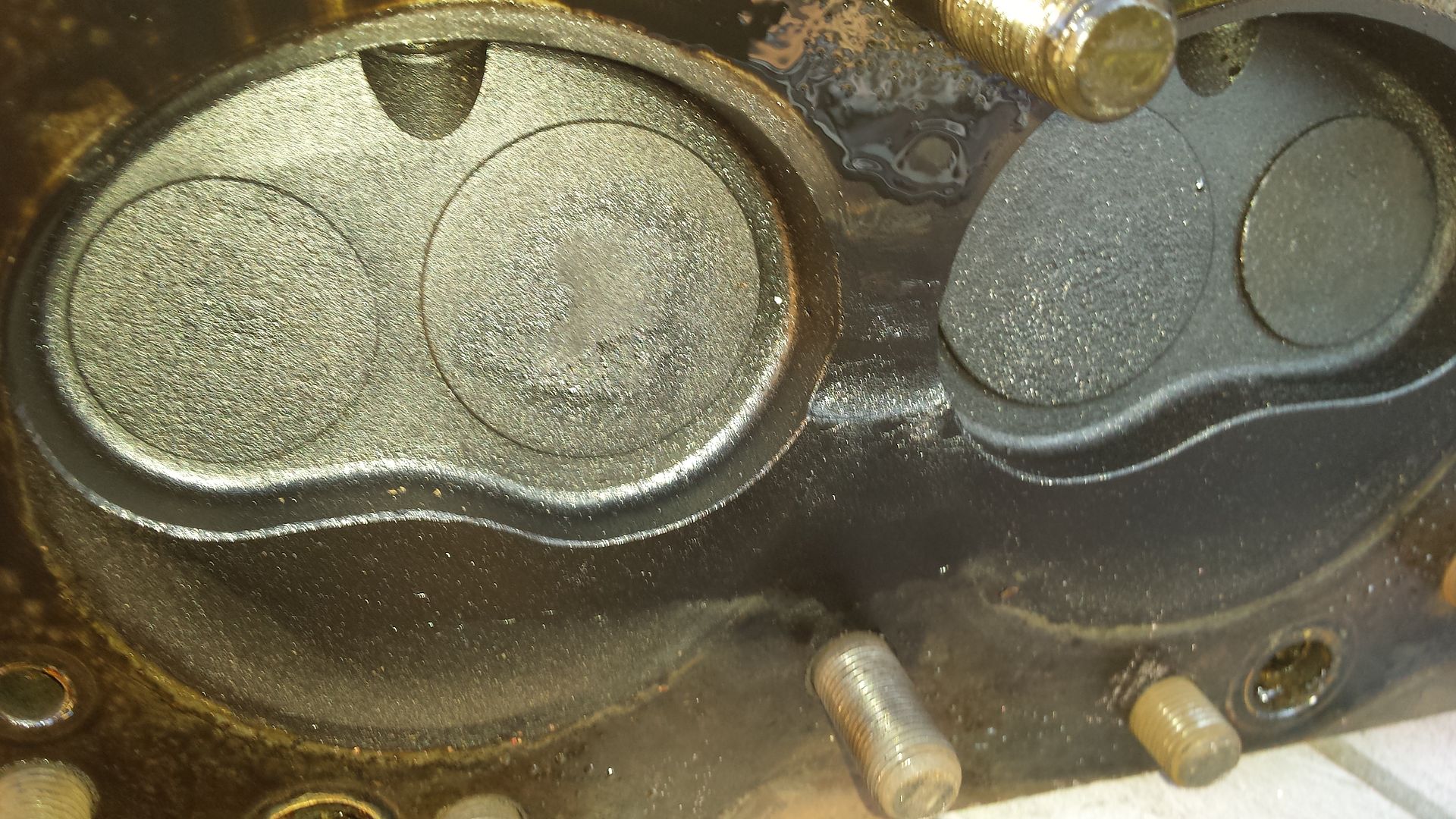

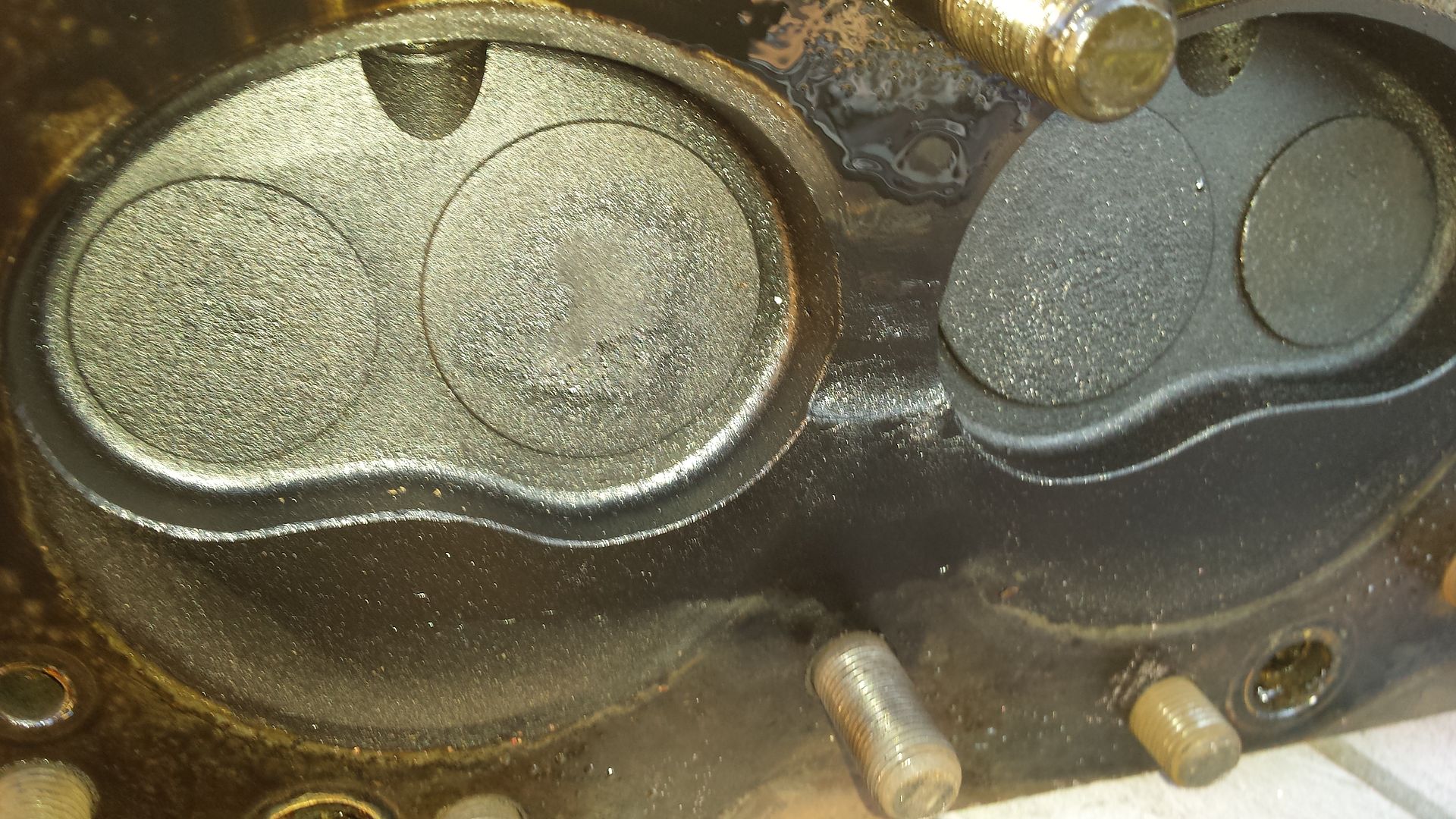

So off came the head and this is what I found:

Impressive for the lack of material between the cylinders!! And a closer inspection of the cylinder head revals an almighty gouge between the valve chambers of #3 and #4 cylinder effectively making the head scrap. I have absolutely no idea why this should have happened.....

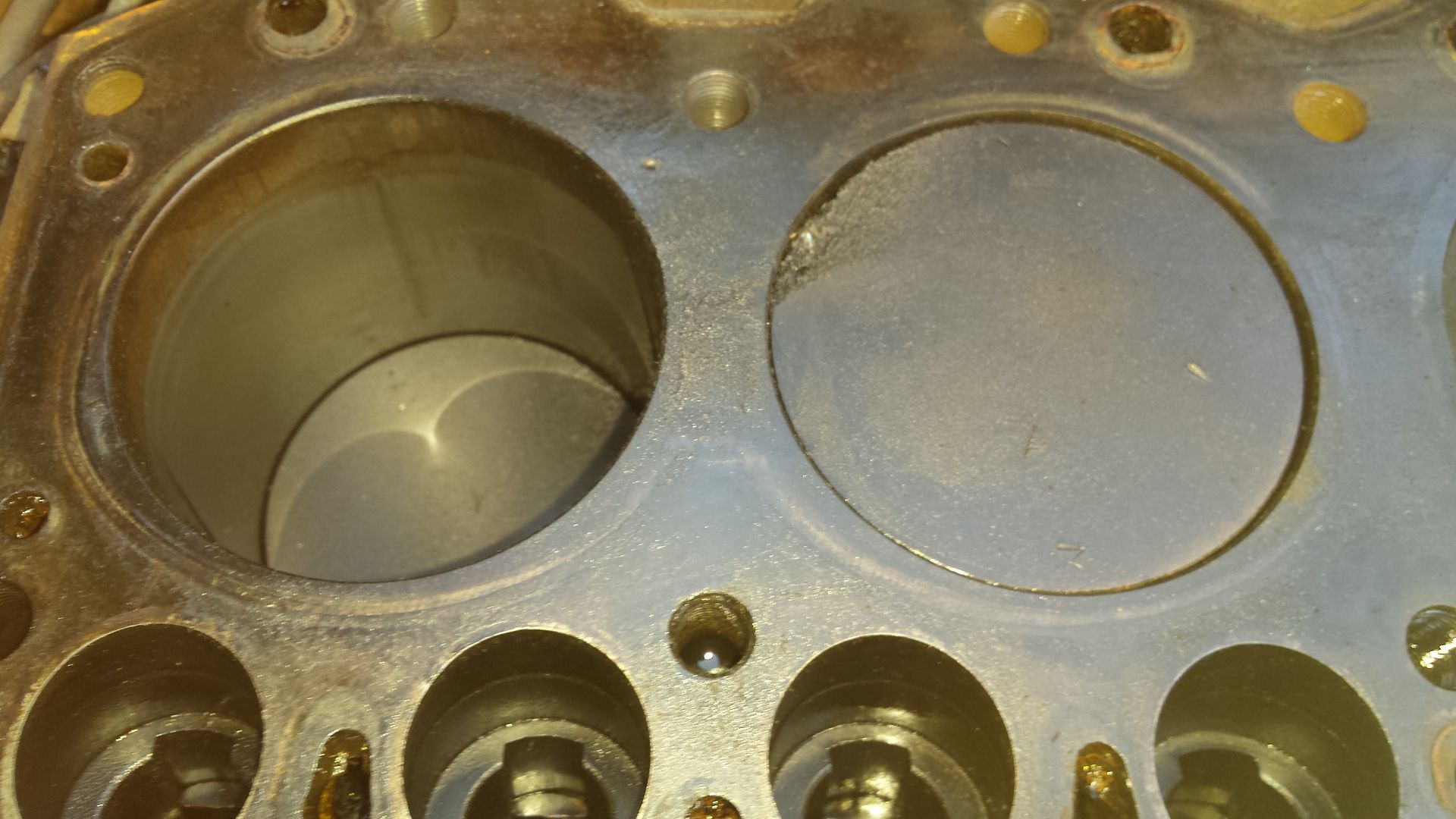

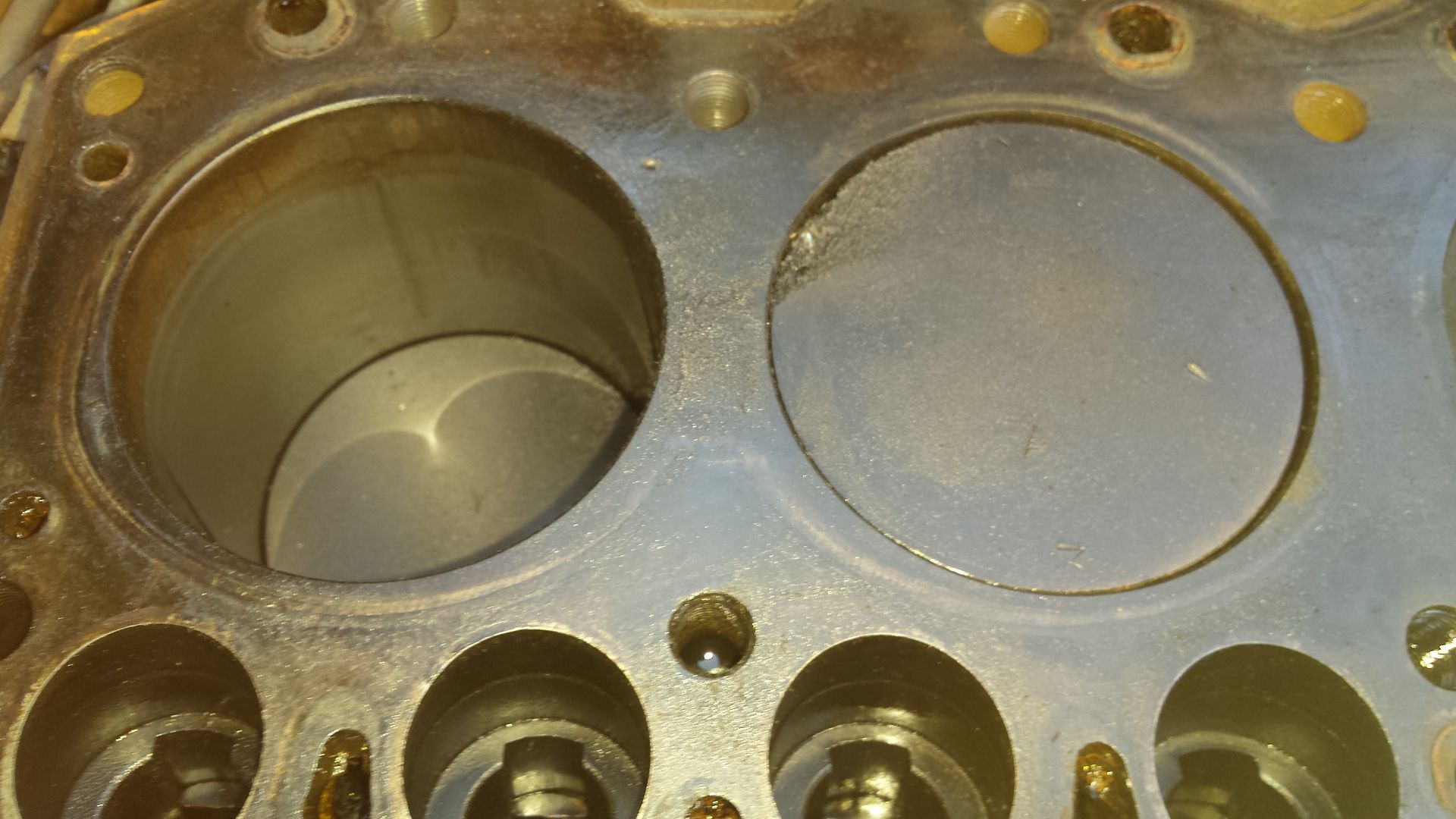

The other noticeable damage was to the piston crowns - all showed signs of erosion where the gasket had failed:

Having located a replacment head it went in the local reconditioning firm to have new valves fitted and be cleaned up as it was extremely rusty. Whilst this was done the pistons were removed and new pistons sourced together with new big end bearings. And now the fun begins. Due to a lack of funds and work space the engine was left in situ in the engine bay but I need to find a way to remove the carbon ridge at the top of the bore. If I leave it there the odds are the new rings will hit it and break first time I run the engine. The bored have been glaze busted with a hone which, of course , had had little effect on the top ridge. I have tried a ridge reamer - but the one I have:

sits on top of the block and is a pig to use as it's almost impossible to keep it square in the bore whilst turning the central shaft. I think I may have to resort to getting hold of a die grinder and trying to use that to tlose the ridge - unless anyone has a better idea????

Meantime the new head has been painted, together with the rocker cover, ready for refitting and the Army oil type stencil applied:

So once this business with the ridge is sorted it should be a simple and straightforwards job of reassembly!!

As with the UAZ - the biggest limiter is the weather as my garage is the front garden!!

However - the current issue is nothing to do with that. Last October i was headed down to Hampshire to collect a Sankey trailer for a friend and as I approached J9 of the M3 with everything running sweetly I felt the dreaded clunking wihch told of a puncture. Pulled over and swapped the wheel over then went to pull away. Engine started fine but suddenly I had no power. I crawled up the J9 slip road and then took 4 attempts to get through the lights, picking up a friendly police escort in the process

Once home I ran a compression check and the source of the problem was immediate:

Cyl #1 - 70 psi

Cyl #2 - 70 psi

Cyl #3 - 0 psi

Cyl #4 - 0 psi

So off came the head and this is what I found:

Impressive for the lack of material between the cylinders!! And a closer inspection of the cylinder head revals an almighty gouge between the valve chambers of #3 and #4 cylinder effectively making the head scrap. I have absolutely no idea why this should have happened.....

The other noticeable damage was to the piston crowns - all showed signs of erosion where the gasket had failed:

Having located a replacment head it went in the local reconditioning firm to have new valves fitted and be cleaned up as it was extremely rusty. Whilst this was done the pistons were removed and new pistons sourced together with new big end bearings. And now the fun begins. Due to a lack of funds and work space the engine was left in situ in the engine bay but I need to find a way to remove the carbon ridge at the top of the bore. If I leave it there the odds are the new rings will hit it and break first time I run the engine. The bored have been glaze busted with a hone which, of course , had had little effect on the top ridge. I have tried a ridge reamer - but the one I have:

sits on top of the block and is a pig to use as it's almost impossible to keep it square in the bore whilst turning the central shaft. I think I may have to resort to getting hold of a die grinder and trying to use that to tlose the ridge - unless anyone has a better idea????

Meantime the new head has been painted, together with the rocker cover, ready for refitting and the Army oil type stencil applied:

So once this business with the ridge is sorted it should be a simple and straightforwards job of reassembly!!

As with the UAZ - the biggest limiter is the weather as my garage is the front garden!!