There's been a major push the last few weeks. I'm sorry to say I've very few photos. Plumbing has been a large part of the work, there was quite a list:

Feed for clutch master cylinder

Intercooler

Oil cooler

Radiator

Power steering

Oil pressure gauge

Temperature gauge

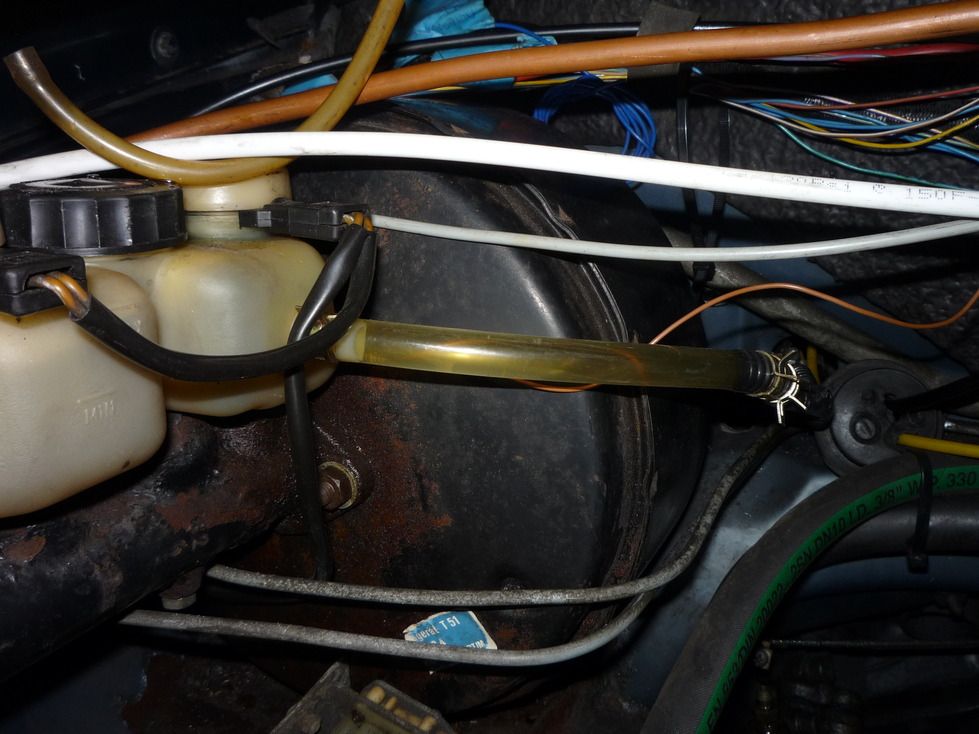

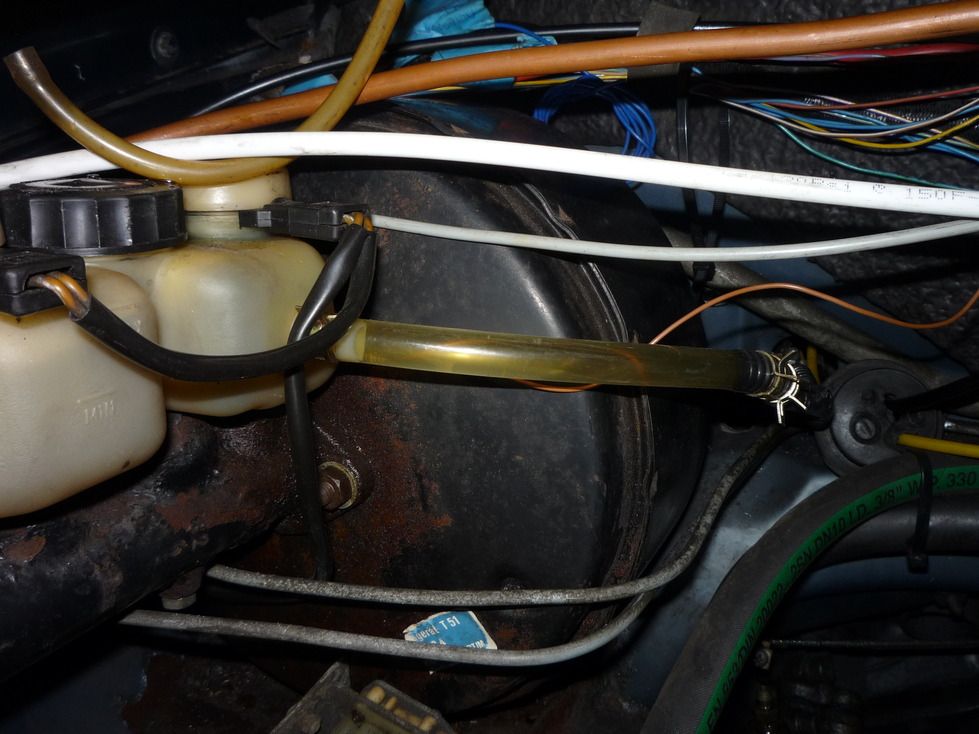

The clutch master cylinder was the easiest part, just a length of hose from the brake reservoir down to the master cylinder.

The intercooler needed a custom pipe to be welded up to get down around the alternator and the anti-roll bar. the intercooler itself isn't permanently attached yet, but fits well between the two front bumper mounts.

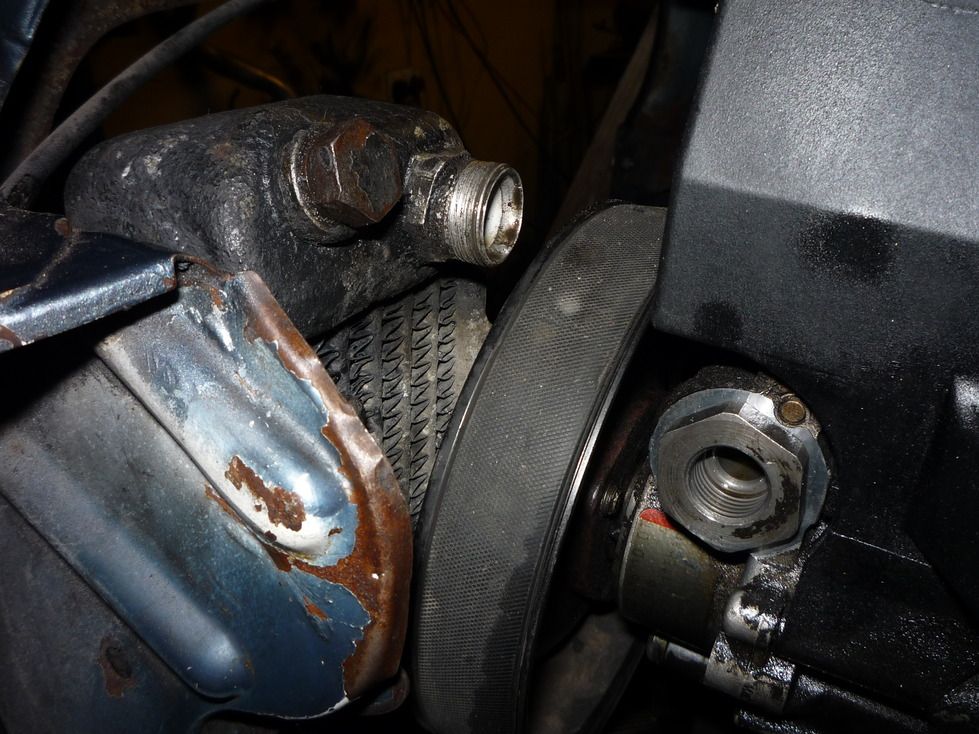

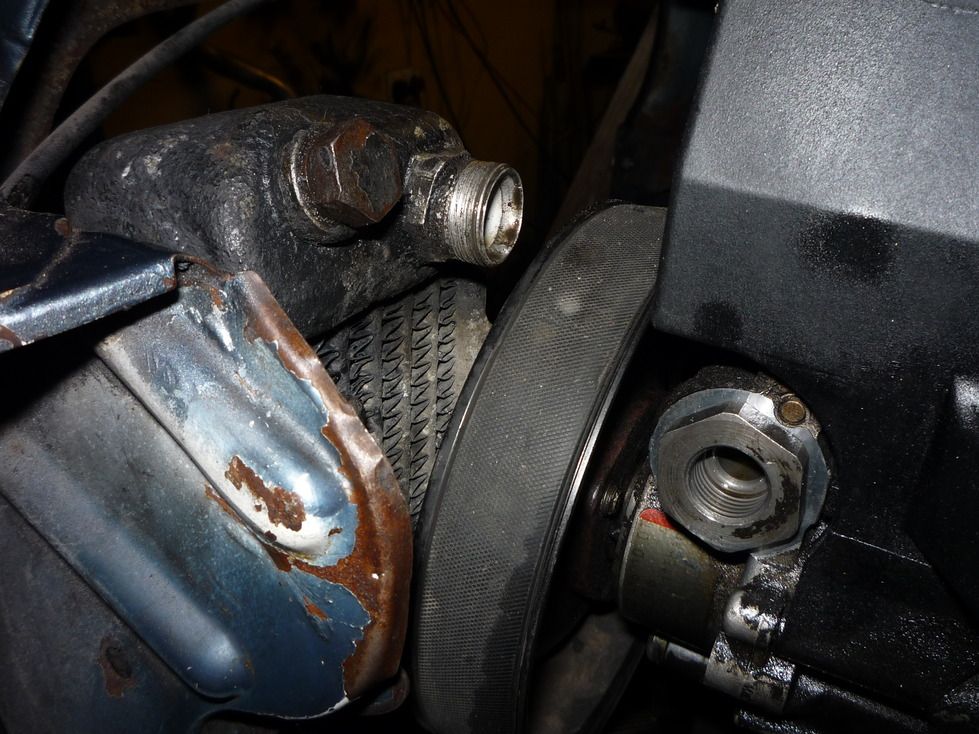

For the oil cooler, it was a bit more involved. In the original car, the oil cooler is actually boldted onto the right side of the radiator, in line with it, so, apart from being unboltable, it is effectively an extension on to the side of the rad. The biggest problem with this was that the oil cooler plumbing on the new engine was on the left hand side. In order to move the cooler to the other side, we had to de-solder the sides off the rad and swap them around. You cna see it in its new position on the left of the rad in this photo:

Once this was done, it was clear that the top connection on the cooler was going to interfere with the power steering pump.

The solution was to swap the outlet position with what used to be the drain plug as the cooler is now upside down. So, we cut the fitting off the W210 E300 oil cooler as there was more meat in those and welded it to the oil cooler from the W108.

The W210 oil cooler:

And the swap job on the W108 cooler:

Once this was all sorted out, the only requirement was to extend the oil feed lines slightly to reach the cooler.

The top connection on the rad is very close to the outlet from the engine, so a bit of bodgery was required to get them connected. I got a couple of tight bends and cut and joined them. It's a little rigid as the engine moves about under power, but I'll try to sort that out by spreading the two halves on the joiner.

The power steering was probably the most awkward to sort out. In terms of plumbing, the guys making up the hydraulic pipes had nothing that would fit the pump end. So, my good welding friend cut the original pump connector and welded it to the hydraulic fitting.

Now, I also knew that the pump output would produce about double the pressure of the old original one, so presumed that hooking my more modern version up to the ancient steering box would result in bad things. So, I bought a gauge for £7.50 from Ebay, and, welding ecxpertise was required again to put together a fitting so that it could be connected to the end of the high pressure pipe.

An evening of testing followed. The pump registered just over 100 bar at the start and I was aiming for around 60. There is a pressure relief valve inside the pump body, a very simple arrangement with a spring that holds a ball bearing against a seat until the pressure pushes it off the seat against the spring. There were a few shims in it, so I went about adjusting with shims. The first try had only minimal impact +/- 2 bar, so adjustment was acheived by shortening the spring with careful application of the angle grinder! 3 or 4 tests later and the pump was outputting about 60 bar.

More welding was required to fit the engine oil presure gauge. There's a nylon pipe running to the back of the pressure gauge in the dash which feeds the pressure up to the mechanical gauge. The diesel engine had a handy bung at the base of the oil filter housing which was removed, drilled out and welded to the fitting from the petrol engine.

The temperature gauge is a vial on the end of a capilliary tube which runs to the back of the dash. The fitting from the petrol engine went straight into a handy hole which was plugged in the diesel without any modification.

If you're still reading, fair play! Here's what I'm getting around to:

[YOUTUBE]_nevB8yOQ0Y[/YOUTUBE]

http://youtu.be/_nevB8yOQ0Y

It works!! The first time in about a year she's moved out of the shed! The drive went well. Gearing is very low as was expected, but I'm very happy with the way the engine behaves. It's hard to tell what it'll be like until you have it on a manual gearbox, but it's great. Clutch and gearbox work nicely too. I'm very happy and really like it. I'll try significantly bigger wheels and tyres shortly. According to my calculations, +2 inches in diameter will have me cruising at 70 and 2,400RPM.

we got rid of that before we lost our licences