W108 Mercedes 280SE diesel conversion project

Re: W108 Mercedes 280SE diesel conversion project

Have you had a look to see if it is possible to fit a "manual" valve block? I won't claim to have any autobox experience (Harvey, you are needed) but there may be one from an earlier model you can pinch parts from to lose the computer and keep the box.

Understeer: when you hit the wall with the front of the car.

Oversteer: when you hit the wall with the back of the car.

Horsepower: how fast you hit the wall.

Torque: how far you take the wall with you.

Oversteer: when you hit the wall with the back of the car.

Horsepower: how fast you hit the wall.

Torque: how far you take the wall with you.

Re: W108 Mercedes 280SE diesel conversion project

That's a good idea Terry, but this box was a big re-design from the previous generation. 5 speeds here instead of 4 and, of course, the addition of all the computery stuff. So, I dont think it would be straight-forward. I certainly cant find any instances of anyone successfully having done this.TerryG wrote:Have you had a look to see if it is possible to fit a "manual" valve block? I won't claim to have any autobox experience (Harvey, you are needed) but there may be one from an earlier model you can pinch parts from to lose the computer and keep the box.

Re: W108 Mercedes 280SE diesel conversion project

I bought a bunch of brownie points with an iPad last week. I've been cashing them in hand over fist over the long weekend, and made some more good progress!

The old 280SE was very reluctant to give up its 3.5L V8. It looks like the designers intended for the engine & 'box to come out through the bottom of the car. Well, I don't have the head room nor the equipent to get the car that high up, so I had to pull the gearbox out from under the car and then lift the engine straight up. It was a real pain getting it all out as every electrical connector was corroded solid, the bolts holding the 'box to the engine were all but inaccessible, the exhaust joints had all rusted solid and I couldn't upen the connections to the oil cooler and didn't want to cut them.

Anyway, it's out now!

I haven't made a detailed study yet, but some stuff I've found out over the weekend:

The 280SE engine bay is about 3cm narrower than the E300 donor car. This shouldn't be a big problem.

The manual gearbox I intend to use is about 11cm shorter than the auto I'm removing. no problem in terms of mounting, but I'll need to extend the prop shaft to meet it.

The rad from the donor is way too big. I'll wait to see what space is like with the new engine fitted before doing naything drastic, but I might have to go buy an aftermarket one.

It looks like the steering box in the 280SE is enormous and might get in the way of the exhaust, but again, I'll see what its like with the engine fitted. I might even explore the possibility of insalling the rack out of the E300 if it works out anyway handy as the old steering box is incontinent and making a mess of my garage floor.

The old 280SE was very reluctant to give up its 3.5L V8. It looks like the designers intended for the engine & 'box to come out through the bottom of the car. Well, I don't have the head room nor the equipent to get the car that high up, so I had to pull the gearbox out from under the car and then lift the engine straight up. It was a real pain getting it all out as every electrical connector was corroded solid, the bolts holding the 'box to the engine were all but inaccessible, the exhaust joints had all rusted solid and I couldn't upen the connections to the oil cooler and didn't want to cut them.

Anyway, it's out now!

I haven't made a detailed study yet, but some stuff I've found out over the weekend:

The 280SE engine bay is about 3cm narrower than the E300 donor car. This shouldn't be a big problem.

The manual gearbox I intend to use is about 11cm shorter than the auto I'm removing. no problem in terms of mounting, but I'll need to extend the prop shaft to meet it.

The rad from the donor is way too big. I'll wait to see what space is like with the new engine fitted before doing naything drastic, but I might have to go buy an aftermarket one.

It looks like the steering box in the 280SE is enormous and might get in the way of the exhaust, but again, I'll see what its like with the engine fitted. I might even explore the possibility of insalling the rack out of the E300 if it works out anyway handy as the old steering box is incontinent and making a mess of my garage floor.

Re: W108 Mercedes 280SE diesel conversion project

That looks like you had a fun and productive day (even if you had some frustrations).

Make the most of your ipad brownie points. From experience they have an expiration date but decorating rooms can top them up again

Make the most of your ipad brownie points. From experience they have an expiration date but decorating rooms can top them up again

Understeer: when you hit the wall with the front of the car.

Oversteer: when you hit the wall with the back of the car.

Horsepower: how fast you hit the wall.

Torque: how far you take the wall with you.

Oversteer: when you hit the wall with the back of the car.

Horsepower: how fast you hit the wall.

Torque: how far you take the wall with you.

Re: W108 Mercedes 280SE diesel conversion project

Edit: Don't follow the instructions in this post, it didn't work! See this post instead!

This is going to be a long post, I hope I've explained what's going on well enough for others to replicate it if they want to!

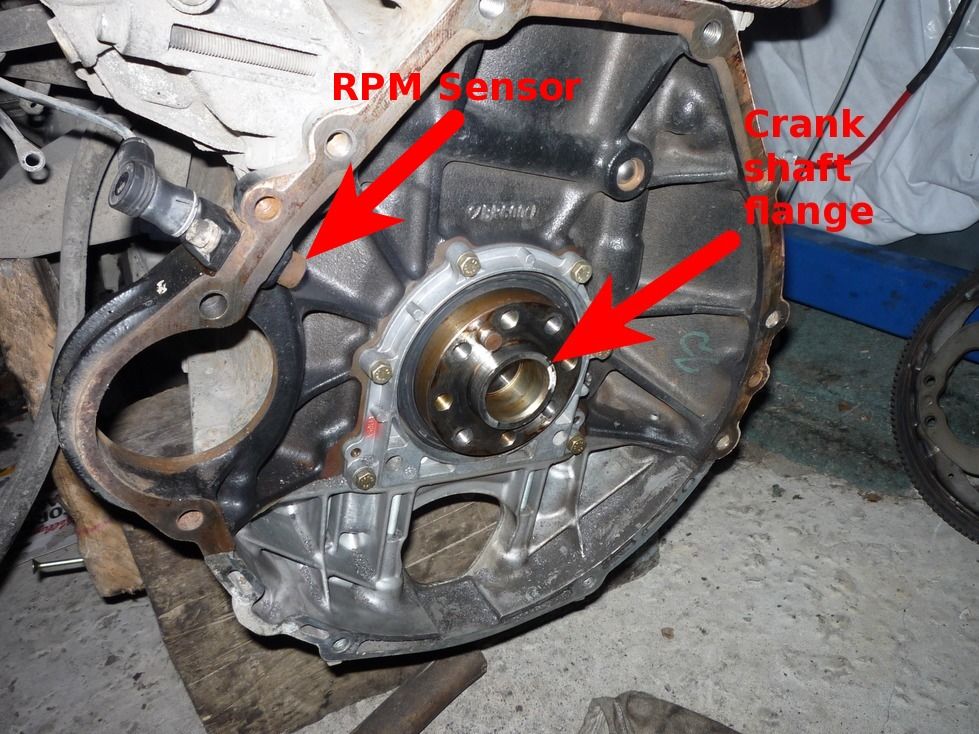

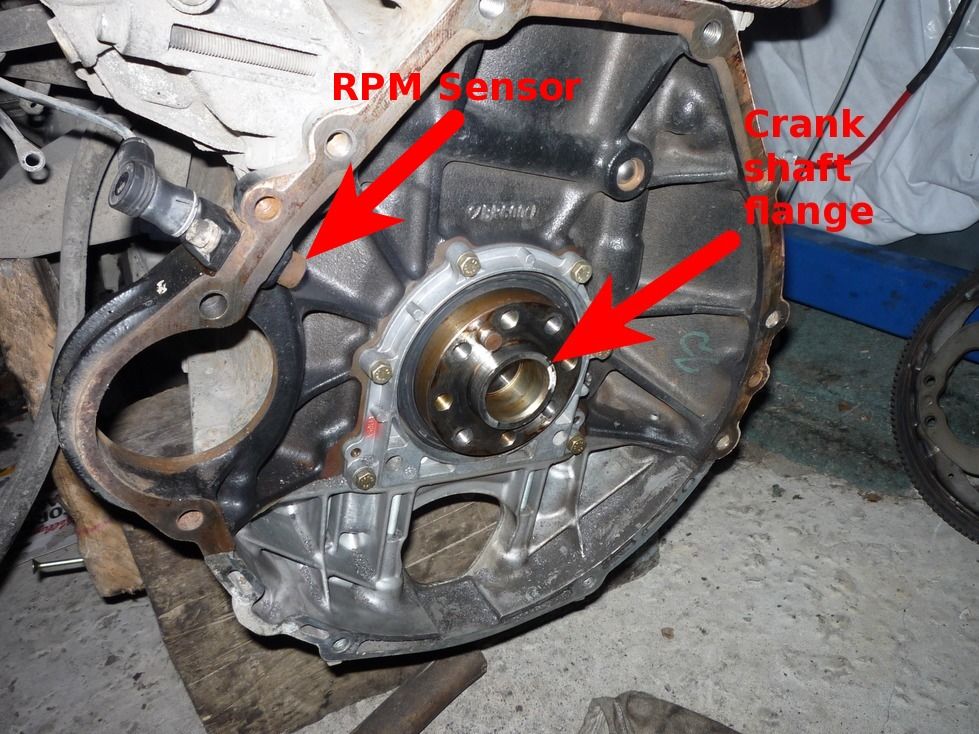

I'm not sure what you call this plate, but this is the original plate which had the ring gear attached to it and sat behind the torque convertor. You might or might not be able to see there are 6 tabs protruding from it which whizz past a sensor which I guess is for an engine speed feed to the ECU rather than a crank position.

The ring with the tabs on it looks pretty crude, but it was obviously machined after being welded on to make it perfectly circular, at least on the outside!

Anyhow, that bit is getting dumped as I'm changing to a manual gearbox. So, I bought one of this on a wing and a prayer. It was listed as a dual mass flywheel conversion kit for a Merc Sprinter van, 2.2CDI and others from 2002 to 2006:

It contained all of these bits:

The first problem I encountered was that there is a protruding flange on the end of the crank shaft, and a corresponding recess in the flywheel. The flange was 11.2mm and the recess only 10mm. This meant that the flywheel could not be tightened right up against the end of the crank, so the crank shaft flange was duly ground back to be shorter than the recess in the back of the flywheel.

Problem number 2 is that the new flywheel is completely surrounded with ribs which, I can only suppose are used to generate a signal for the Merc Sprinter it was intended to be used in.

These ribs also slightly contact the sensor. Plan "A" was to machine away the ribs I don't need in order to leave 6 remaining, simulating what was in place before, I could then put a spacer behind the sensor so that it didnt stick out so far and wasn't hit by the remaining ribs. The main issues with plan "A" were that the ribs weren't in the same place on the flywheel as the tabs on the original item (I'm not absolutely sure that there isn't some kind of timing function along with RPM!), and that I would then need to have the flywheel balanced.

I have a great engineering friend who came up with a far superior plan "B": We would drill the 6 'valleys' which correspond to the tabs we had removed, tap them and screw in bolts which would protrude above the existing ribs. We'd have to move the sensor even further out, but that's no big deal, and we wouldn't be disturbing the balance of the flywheel. So, to the implementation of plan "B".

We marked the valleys which were to be drilled and tapped, then mounted the flywheel on the engine. We turned down a big bolt so that it matched the shaft size of the sensor and would fit snugly in the sensors mounting hole. We then drilled a hole down the centre of the bolt and poked the bolt into the sensor hole. Now, we had a guide which we could use to make sure the holes we drilled were directly beneath where the sensor would be.

Here's the sensor fitment:

and the bolt we guntered into a tool:

and some drilling underway:

Here's a bolt inserted in the hole. I plan to get longer bolts, loctite them home and then remove the heads so that the part left sticking out proud of the ribs is closer to the 5.5mm of the tabs which were originally present.

Aside from these alterations, Everything else seems to work out in terms of the position of the bearing which accepts the end of the spigot shaft, the position of the clutch friction plate in relation to the splined part of the spigot shaft, and the position of the pressure plate in relation to the release bearing/concentric slave culinder which is mounted in the gearbox. Happy days!

This is going to be a long post, I hope I've explained what's going on well enough for others to replicate it if they want to!

I'm not sure what you call this plate, but this is the original plate which had the ring gear attached to it and sat behind the torque convertor. You might or might not be able to see there are 6 tabs protruding from it which whizz past a sensor which I guess is for an engine speed feed to the ECU rather than a crank position.

The ring with the tabs on it looks pretty crude, but it was obviously machined after being welded on to make it perfectly circular, at least on the outside!

Anyhow, that bit is getting dumped as I'm changing to a manual gearbox. So, I bought one of this on a wing and a prayer. It was listed as a dual mass flywheel conversion kit for a Merc Sprinter van, 2.2CDI and others from 2002 to 2006:

It contained all of these bits:

The first problem I encountered was that there is a protruding flange on the end of the crank shaft, and a corresponding recess in the flywheel. The flange was 11.2mm and the recess only 10mm. This meant that the flywheel could not be tightened right up against the end of the crank, so the crank shaft flange was duly ground back to be shorter than the recess in the back of the flywheel.

Problem number 2 is that the new flywheel is completely surrounded with ribs which, I can only suppose are used to generate a signal for the Merc Sprinter it was intended to be used in.

These ribs also slightly contact the sensor. Plan "A" was to machine away the ribs I don't need in order to leave 6 remaining, simulating what was in place before, I could then put a spacer behind the sensor so that it didnt stick out so far and wasn't hit by the remaining ribs. The main issues with plan "A" were that the ribs weren't in the same place on the flywheel as the tabs on the original item (I'm not absolutely sure that there isn't some kind of timing function along with RPM!), and that I would then need to have the flywheel balanced.

I have a great engineering friend who came up with a far superior plan "B": We would drill the 6 'valleys' which correspond to the tabs we had removed, tap them and screw in bolts which would protrude above the existing ribs. We'd have to move the sensor even further out, but that's no big deal, and we wouldn't be disturbing the balance of the flywheel. So, to the implementation of plan "B".

We marked the valleys which were to be drilled and tapped, then mounted the flywheel on the engine. We turned down a big bolt so that it matched the shaft size of the sensor and would fit snugly in the sensors mounting hole. We then drilled a hole down the centre of the bolt and poked the bolt into the sensor hole. Now, we had a guide which we could use to make sure the holes we drilled were directly beneath where the sensor would be.

Here's the sensor fitment:

and the bolt we guntered into a tool:

and some drilling underway:

Here's a bolt inserted in the hole. I plan to get longer bolts, loctite them home and then remove the heads so that the part left sticking out proud of the ribs is closer to the 5.5mm of the tabs which were originally present.

Aside from these alterations, Everything else seems to work out in terms of the position of the bearing which accepts the end of the spigot shaft, the position of the clutch friction plate in relation to the splined part of the spigot shaft, and the position of the pressure plate in relation to the release bearing/concentric slave culinder which is mounted in the gearbox. Happy days!

Last edited by pryantcc on Thu May 15, 2014 10:15 pm, edited 2 times in total.

Re: W108 Mercedes 280SE diesel conversion project

Excellent update! You're a) brave and b) clever!

Great pics and well explained, following this thread with great interest!

Cheers

Great pics and well explained, following this thread with great interest!

Cheers

Some people are like Slinkies - they serve no useful purpose, but they still bring a smile to your face when you push them downstairs.

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: W108 Mercedes 280SE diesel conversion project

+1

I have to confess that I have a soft spot for these Mercs - they are from an era when quality and durability still meant something!

I have to confess that I have a soft spot for these Mercs - they are from an era when quality and durability still meant something!

Re: W108 Mercedes 280SE diesel conversion project

Well, plan B turned out to be a bit of a disaster! I attached the modified flywheel to the engine, and after setting the height of the RPM sensor so that my newly attached studs didn't hit it, we hooked up fuel and sealed up the oil & water pipes after a emptying a can of water in and seeing it flow across the floor! My self and a friend hoisted the engine up on the engine crane, hooked up a battery and hit ths starter. There was the usual click of the starter followed very closely by a thump, and the engine was locked solid!

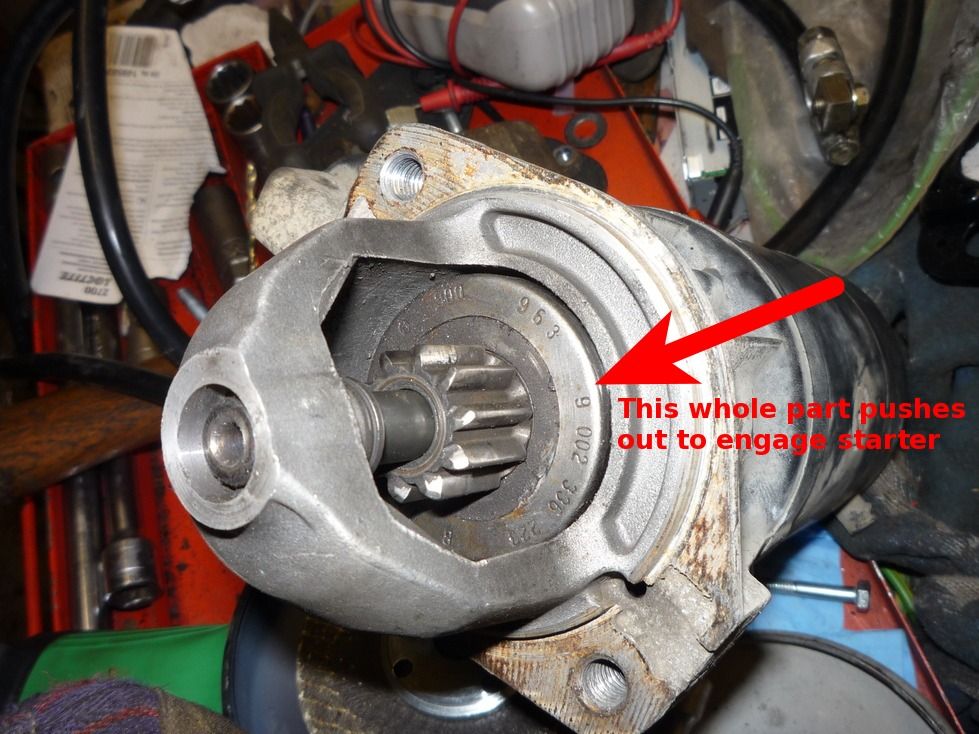

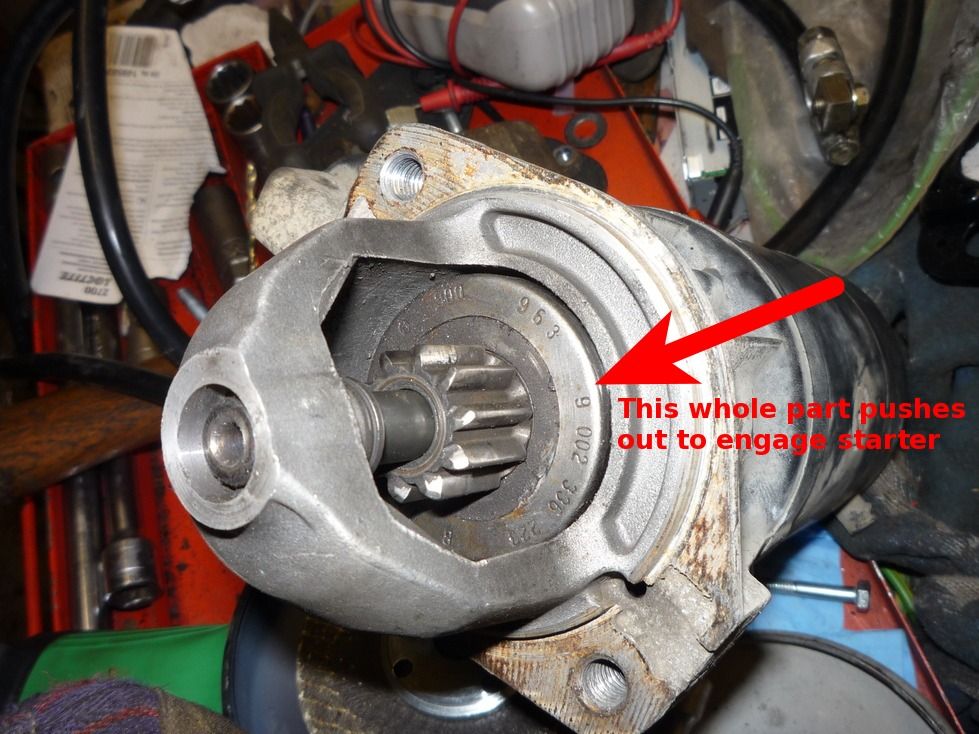

It turns out that it isn't just the gear on the end of the starter which pos out to engage with the ring gear, most of the end of the starter comes with it!

So, while the starter was engaged, the studs would whack straight into it and the flywheel do no more than 1/6 of a rotation.

Plan A was re-hashed to become plan C and required some more extreme flywheel modification. The studs which we had inserted were removed with great difficulty. The Loctite we used had "Extra Strong" or something along those lines written on the bottle. It was amazing, the studs were locked solid after only an hour ror two! So much so that 2 of them broke off when trying to get them out!

My friend set the flywheel up in his lathe and cut down all of the ribs from around the outer edge, then fitted new studs in the old holes and turned them down to the appropriate size.

Here's how it was before:

And after:

And a closeup:

Now the flywheel is re-attached, the RPM sensor located appropriately and the engine runs suspended from the engine crane! It's a bit cold, and smoky as a reslt, but works fine.

I don't know how to embed a video, but you can see the startup on youtube here.

To say that I'm a happy camper would be an understatement! So, now on with the rest of the work: making engine mounting brackets, making clutch pedal assembly, adapting drive shaft, etc...

It turns out that it isn't just the gear on the end of the starter which pos out to engage with the ring gear, most of the end of the starter comes with it!

So, while the starter was engaged, the studs would whack straight into it and the flywheel do no more than 1/6 of a rotation.

Plan A was re-hashed to become plan C and required some more extreme flywheel modification. The studs which we had inserted were removed with great difficulty. The Loctite we used had "Extra Strong" or something along those lines written on the bottle. It was amazing, the studs were locked solid after only an hour ror two! So much so that 2 of them broke off when trying to get them out!

My friend set the flywheel up in his lathe and cut down all of the ribs from around the outer edge, then fitted new studs in the old holes and turned them down to the appropriate size.

Here's how it was before:

And after:

And a closeup:

Now the flywheel is re-attached, the RPM sensor located appropriately and the engine runs suspended from the engine crane! It's a bit cold, and smoky as a reslt, but works fine.

I don't know how to embed a video, but you can see the startup on youtube here.

To say that I'm a happy camper would be an understatement! So, now on with the rest of the work: making engine mounting brackets, making clutch pedal assembly, adapting drive shaft, etc...

Last edited by pryantcc on Thu May 15, 2014 10:39 pm, edited 3 times in total.

Re: W108 Mercedes 280SE diesel conversion project

This is not only inspiring, it's also pioneering work as soon enough, more classic folk who want their cars to be viable as forms of transport - rather than just display pieces - in the era of expensive fuel and electronic everything will be looking to do similar conversions. I like the way in which you just get on and make it happen and are clearly not afraid to try, try again until it works!

J

"Home is where you park it", so the saying goes. That may yet come true..

"Home is where you park it", so the saying goes. That may yet come true..

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: W108 Mercedes 280SE diesel conversion project

I reckon this is what an ex-boss would have called proper engineering: fly by the seat of your pants stuff and not just "slap another part in and see what happens".

Just think, in another ten years, we'll have cheap hybrid motors available - I wonder if I'll be around to read how you are converting the Merc to battery power because the EU has banned diesels because they emit even more harmful substances than they now do. You think they'd have spotted what comes out of a diesel exhaust some time ago!

Just think, in another ten years, we'll have cheap hybrid motors available - I wonder if I'll be around to read how you are converting the Merc to battery power because the EU has banned diesels because they emit even more harmful substances than they now do. You think they'd have spotted what comes out of a diesel exhaust some time ago!

Who is online

Users browsing this forum: No registered users and 170 guests