A Landy is reborn

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

It was a day of two halves today! I got a reasonable start and managed to get the steering sorted and tightened up by eleven, in spite of a couple of Jehovah's Witnesses interrupting me! I was so pleased that I decided to empty the waste oil bowl into the old can. It nearly went in - there was more than I thought but I was lucky: the funnel was quite a neat fit in the can, so I was able to get it over the bowl without making a mess on the floor.

I was in such a good mood that I put some brake fluid in the master cylinder and opened a few bleed nipples and pressed the brake pedal a few times - and actually managed to bleed the offside rear brake without problems! However, I found three loose unions - one on the rear flexi, one on the bottom nsf wheel cylinder and one loose bleed nipple. all were soon sorted. It was lunchtime by then, so we had a break and went back after our post-lunch nap. I dug out the Gunson Easy-Bleed and, after a bit of sorting and a bit of fluid blasting out of the top of the master cylinder (just needed the "cap" tightening a bit more), I got the brakes bled without any major problems.

I was so flushed with success that I took the alternator off so I could sort the bolt head that fouls the mounting bolt. I was doing quite well, but Phil showed up and we had a look at the nice clean back brakes and the new pool of brake fluid on the floor! It serves me right - I should have changed the back wheel cylinders after seeing how bad the front ones were!! I've taken the nsr drum and linings off - luckily there was only a small fluid stain on one of the linings - it hadn't even soaked into it and a little brake cleaner soon sorted it out. A pair of new wheel cylinders have been ordered (they were cheaper than a single one from my usual supplier and I might be keen (or obsessive) enough to change the pair!

As I didn't get the alternator mount sorted, it will be the first job tomorrow. Then I will make a start on the wiring - it's an interesting Monrego/Land Rover lash-up at the moment and it will be even more interesting trying to make sense of it!

I was in such a good mood that I put some brake fluid in the master cylinder and opened a few bleed nipples and pressed the brake pedal a few times - and actually managed to bleed the offside rear brake without problems! However, I found three loose unions - one on the rear flexi, one on the bottom nsf wheel cylinder and one loose bleed nipple. all were soon sorted. It was lunchtime by then, so we had a break and went back after our post-lunch nap. I dug out the Gunson Easy-Bleed and, after a bit of sorting and a bit of fluid blasting out of the top of the master cylinder (just needed the "cap" tightening a bit more), I got the brakes bled without any major problems.

I was so flushed with success that I took the alternator off so I could sort the bolt head that fouls the mounting bolt. I was doing quite well, but Phil showed up and we had a look at the nice clean back brakes and the new pool of brake fluid on the floor! It serves me right - I should have changed the back wheel cylinders after seeing how bad the front ones were!! I've taken the nsr drum and linings off - luckily there was only a small fluid stain on one of the linings - it hadn't even soaked into it and a little brake cleaner soon sorted it out. A pair of new wheel cylinders have been ordered (they were cheaper than a single one from my usual supplier and I might be keen (or obsessive) enough to change the pair!

As I didn't get the alternator mount sorted, it will be the first job tomorrow. Then I will make a start on the wiring - it's an interesting Monrego/Land Rover lash-up at the moment and it will be even more interesting trying to make sense of it!

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

I had hoped to make a start on refitting some body panels last week, but the brakes will need bleeding again when the new wheel cylinders have been fitted (even though I have capped the pipe on the one that leaked. However, the wheel cylinders I ordered on eBay got lost in the post! I sent the seller a message yesterday, he confirmed that UK Mail had lost them and has posted a replacement pair by Royal Mail.

The UK Mail man arrived with the wheel cylinders half an hour ago, so my afternoon's job has changed!

As I couldn't get on with the brakes, I returned to the alternator and quickly cured the problem of the badly placed mounting bolt - I sheered the head off when trying to remove it! As the bracket is well secured, I haven't bothered to drill the remains out and fit another one.

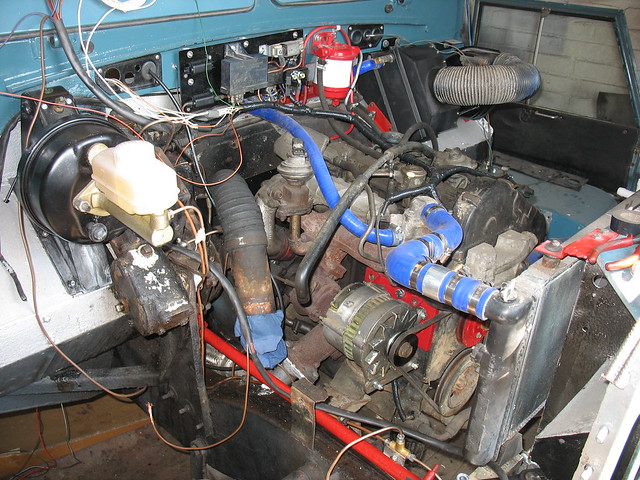

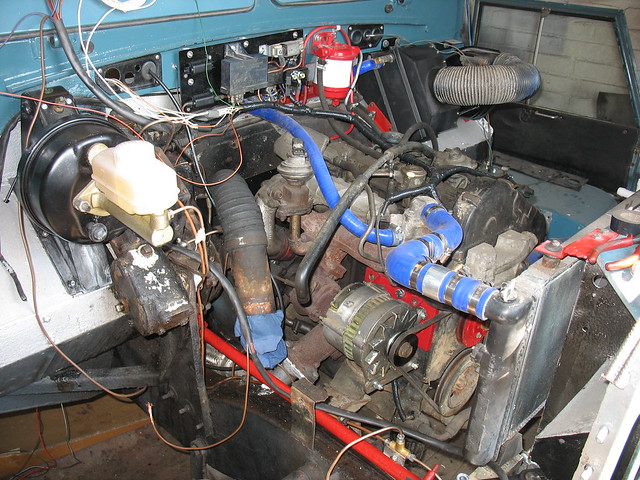

I then decided to attack the engine wiring as it has always been a nightmare and the heaters didn't seem to work properly. It took nearly an hour to get all the tape and sleeving off the harness and find some amazing bodge/codge jobs that the lad did when he fitted the engine!

I have also made a harness for the RH front end (ie alternator, lights horn and rad fan etc), but can't fix it in place until the wing is on again (part of the bodywork I wanted to do last week!).

The wiring as it is at the moment:

Most of what you can see will be removed as it is redundant EGR stuff - or Montego stuff for other "systems".

I have made a new panel for the engine heater relays etc, main battery connection and two "main" fuses (main supply and heater plugs) and have test fitted it - the six silver "discs" are riv-nuts to hold the panel in place.

The photo makes the bolts look black - it's just reflection though! Typically, where I have many hundreds of imperial bolts, I have a few dozen metric ones and the riv-nuts are metric. "Spout bolts" were the only 6mm set screws that weren't too long. However, they are "flanged" (big"), so work well on the plastic bits!

I must remember to fit the blade fuses when I do the wiring - I suspect I'll forget and wonder why nothing works!

The UK Mail man arrived with the wheel cylinders half an hour ago, so my afternoon's job has changed!

As I couldn't get on with the brakes, I returned to the alternator and quickly cured the problem of the badly placed mounting bolt - I sheered the head off when trying to remove it! As the bracket is well secured, I haven't bothered to drill the remains out and fit another one.

I then decided to attack the engine wiring as it has always been a nightmare and the heaters didn't seem to work properly. It took nearly an hour to get all the tape and sleeving off the harness and find some amazing bodge/codge jobs that the lad did when he fitted the engine!

I have also made a harness for the RH front end (ie alternator, lights horn and rad fan etc), but can't fix it in place until the wing is on again (part of the bodywork I wanted to do last week!).

The wiring as it is at the moment:

Most of what you can see will be removed as it is redundant EGR stuff - or Montego stuff for other "systems".

I have made a new panel for the engine heater relays etc, main battery connection and two "main" fuses (main supply and heater plugs) and have test fitted it - the six silver "discs" are riv-nuts to hold the panel in place.

The photo makes the bolts look black - it's just reflection though! Typically, where I have many hundreds of imperial bolts, I have a few dozen metric ones and the riv-nuts are metric. "Spout bolts" were the only 6mm set screws that weren't too long. However, they are "flanged" (big"), so work well on the plastic bits!

I must remember to fit the blade fuses when I do the wiring - I suspect I'll forget and wonder why nothing works!

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

Tractorman is not a happy cuddly rabbit. Britpart have managed to supply a wheel cylinder which leaks! Not only that, but it isn't the one that replaced a leaking cylinder; oh no, I decided that, as there was only one original cylinder left (all the others had problems!), I would change BOTH the back wheel cylinders. The new leaky one has replaced a perfectly serviceable original that didn't leak one drop! To add to the annoyance - it only leaks when you press the pedal (or bleed the system with the Easy-bleed), so I didn't spot it straight away - it was the next morning when I saw a pool of fluid on the floor and decided to take the drum off. The "end cap" holds the fluid long enough for me not to see it when I press the pedal and lets the fluid seep out slowly later on!!

The towels were left overnight (the top one was under the wheel cylinder). It doesn't look like a lot of fluid, but there was about 15ml in the brake drum yesterday morning - fortunately there wasn't enough to get to the linings. The towel on the right collected that much fluid in three hours, but the one below the brake was left about twelve hours (overnight). I know it looks more than it probably is - but there shouldn't be any leaks at all!!

So I have ordered a decent wheel cylinder from one of my "preferred" suppliers and that's another week lost - where I should have been sorting the diff oil seal and then the seatbox, which would have got me close to "mobility"!

However, I spent this morning doing some more wiring and have the various cables fitted to the engine (but not elsewhere) and the next job will be to make that into a harness of some sort and connect the new panel (which is part-wired up too). If I can get that lot connected up (even if it is a temporary job until the dash is refitted), I should be able to start the engine. That may boost the enthusiasm a little!

The towels were left overnight (the top one was under the wheel cylinder). It doesn't look like a lot of fluid, but there was about 15ml in the brake drum yesterday morning - fortunately there wasn't enough to get to the linings. The towel on the right collected that much fluid in three hours, but the one below the brake was left about twelve hours (overnight). I know it looks more than it probably is - but there shouldn't be any leaks at all!!

So I have ordered a decent wheel cylinder from one of my "preferred" suppliers and that's another week lost - where I should have been sorting the diff oil seal and then the seatbox, which would have got me close to "mobility"!

However, I spent this morning doing some more wiring and have the various cables fitted to the engine (but not elsewhere) and the next job will be to make that into a harness of some sort and connect the new panel (which is part-wired up too). If I can get that lot connected up (even if it is a temporary job until the dash is refitted), I should be able to start the engine. That may boost the enthusiasm a little!

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

Well, the new wheel cylinder arrived yesterday (a Delphi one) and it doesn't leak! However, there was a leak at the union where the pipe joins. As the pipe has been on and off more times than the proverbial whore's drawers, I have trimmed the pipe and put a new flare on. There was just a drip on the newest (of many) paper towels this evening and it might just be the remains of the stuff that came out of the other new (Britpart) cylinder, so I suspect it's a case of "job sorted" (and then gave the pipe an extra nip up, just in case!). The next job should be to get rid of more air - I did bleed that cylinder, I could reach it while I had my foot on the brake pedal, but suspect the system will need proper old-fashioned two-man bleeding as the easy-bleed doesn't seem too successful in removing the last of the air!

This was the leak this morning (the cylinder was fitted yesterday afternoon)

I'm slowly progressing with the wiring, not as quickly as I had hoped but I have had to order more cable - twice!

One lack of forethought: I used some box-section ally to make three stand-offs for the new panel, which you can just about see in the photos. I should have made six separate ones though: I can't hide the main alternator leads behind the panel now!

However, it's certainly looking better than it did when I bought it:

I've bought a cheap cone-type air filter to use instead of the grotty Montego one. I'll have to sort something out for the intake pipe though; the one that's there at the moment is rather a neat fit on the turbo as the bulkhead is very close to the back and side of the engine and the pipe has to go through 180deg in the tight space. However, after dropping a bullet that I was about to solder into the depths, I have blocked the air intake with an old tee shirt (at last)!

This was the leak this morning (the cylinder was fitted yesterday afternoon)

I'm slowly progressing with the wiring, not as quickly as I had hoped but I have had to order more cable - twice!

One lack of forethought: I used some box-section ally to make three stand-offs for the new panel, which you can just about see in the photos. I should have made six separate ones though: I can't hide the main alternator leads behind the panel now!

However, it's certainly looking better than it did when I bought it:

I've bought a cheap cone-type air filter to use instead of the grotty Montego one. I'll have to sort something out for the intake pipe though; the one that's there at the moment is rather a neat fit on the turbo as the bulkhead is very close to the back and side of the engine and the pipe has to go through 180deg in the tight space. However, after dropping a bullet that I was about to solder into the depths, I have blocked the air intake with an old tee shirt (at last)!

Re: A Landy is reborn

Looks great, I'd agree with the old school brake bleeding. I find the easibleed great for changing the fluid but a little bit of old school gets all the air out.

Kev

Kev

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

I gave the union another nip up this morning, though I suspect that, had the paper towel not been in place, I wouldn't have known there was a leak!

I had intended making a start on the lower dash today - there's a lot of metal to be replaced! However, I remembered that one important job was that dreaded diff oil seal. I had already marked the bolt, flange and the shaft so I could get things back in the right place when I counted the turns of the nut (there's a crush-tube on the pinion shaft and the "best" way to refit the flange nut is to count turns). However, even with a four foot long pipe on the breaker bar, the nut wouldn't move! Unfortunately, two quick blasts with the windy gun took the nut straight off - with no chance to count the turns I gather a suitable guesstimate is to tighten the nut until it "suddenly" becomes tight and then give it another third to half a turn. I'm also going to use a little thread locking stuff as, apparently, the nut can work loose even though it should go tighter in use. I'd have done it this evening, but my apprentice was complaining about not getting her meal break at the right time and I wanted to get a good look at my marks in daylight before finally tightening things up. Not that it should matter if I use the "tighten till tight and add a bit" method.

I gather a suitable guesstimate is to tighten the nut until it "suddenly" becomes tight and then give it another third to half a turn. I'm also going to use a little thread locking stuff as, apparently, the nut can work loose even though it should go tighter in use. I'd have done it this evening, but my apprentice was complaining about not getting her meal break at the right time and I wanted to get a good look at my marks in daylight before finally tightening things up. Not that it should matter if I use the "tighten till tight and add a bit" method.

I had intended making a start on the lower dash today - there's a lot of metal to be replaced! However, I remembered that one important job was that dreaded diff oil seal. I had already marked the bolt, flange and the shaft so I could get things back in the right place when I counted the turns of the nut (there's a crush-tube on the pinion shaft and the "best" way to refit the flange nut is to count turns). However, even with a four foot long pipe on the breaker bar, the nut wouldn't move! Unfortunately, two quick blasts with the windy gun took the nut straight off - with no chance to count the turns

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

Phil turned up ten days ago and we attacked the brakes - without success! I fear the cheap master cylinder has problems with lack of use (I bought it nearly a year ago and suspect it wasn't a quality make from the lack of markings on the barrel). I ordered a correct (for the year) master cylinder and will have to alter the system back to single-circuit in the that, when Phil comes back from his holidays, he will have time to repeat the bleeding process (the easy-bleed doesn't have the right cap and I don't want to drill the nice new one on the master cylinder!).

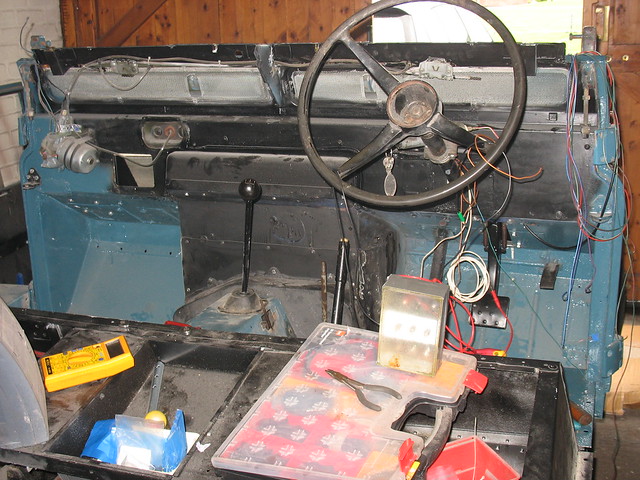

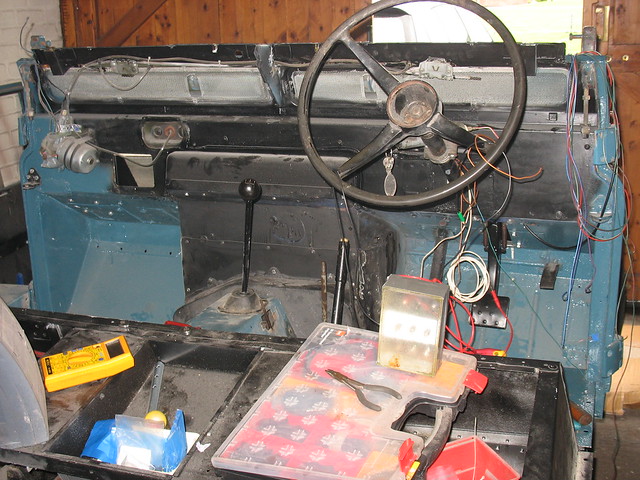

So, back to the wiring. I've put a few more leads and a relay (for the starter solenoid) on the new panel:

Note the air intake is lacking the tee-shirt - more on that later!

The ignition switch has been checked and wired up:

Note that the charger is working -and that the floors is in place(ish).

Note the crimped and soldered terminals! There's only one reason for the heavy live feed cable )the brown one): I haven't got anything smaller! I can't make much progress from here (like clipping the cables to the bulkhead) as the lower dash needs to be in place first - and it needs to have a few (lots of) rusty bits cut out and replaced with nice new metal - and some new foam and leather cloth!

So, with the ignition wired up, the next job was to make some battery clamps/stays and connect the battery:

So I had a battery in place and ignition wired up. Almost enough to start the engine! There was just the alternator, oil pressure and heater warning lights to wire up. I made a "lamp box" to use as temporary test lamps (an old plastic box with individual sockets to each bulb) and connected them up.

Oh yes, add some white HIPS sheet and duct tape to the "parts list" for the lamp box!

So everything was in place to start the engine! I switched the ignition on with my teeth (I had my fingers in my ears, just in case!) and the heater warning light came on for five seconds and clicked off nicely. However, the alternator light didn't come on! After a slight panic, I disconnected the lead that goes from the alternator "light" to the second heater relay (which shorts the shunt resistor) and the alternator light now works nicely too. I suspect the wise person would leave the heater relay off, but I might try a couple of diodes in the leads and see if that cures the problem. As there was no smoke coming off anything, the next step was to try starting the engine! Try was the operative word as, after ten seconds there was no sign of life, a second burst didn't fare any better. It was then I remembered that there was a tee shirt in the air intake! With that obstruction removed, I tried the starter again and the engine tried to fire, but the battery was too flat to have the desired result.

So it was out with the charger and I left it charging for about three hours while I had lunch and walked the dog. I went back and gave it another go and, although the battery wasn't fully charged, it started almost straight away. I stopped the engine almost as soon as I had it running as there isn't any water in it (no header tank on yet). So the Land Rover lives again - and I am somewhat relieved.

So, back to the wiring. I've put a few more leads and a relay (for the starter solenoid) on the new panel:

Note the air intake is lacking the tee-shirt - more on that later!

The ignition switch has been checked and wired up:

Note that the charger is working -and that the floors is in place(ish).

Note the crimped and soldered terminals! There's only one reason for the heavy live feed cable )the brown one): I haven't got anything smaller! I can't make much progress from here (like clipping the cables to the bulkhead) as the lower dash needs to be in place first - and it needs to have a few (lots of) rusty bits cut out and replaced with nice new metal - and some new foam and leather cloth!

So, with the ignition wired up, the next job was to make some battery clamps/stays and connect the battery:

So I had a battery in place and ignition wired up. Almost enough to start the engine! There was just the alternator, oil pressure and heater warning lights to wire up. I made a "lamp box" to use as temporary test lamps (an old plastic box with individual sockets to each bulb) and connected them up.

Oh yes, add some white HIPS sheet and duct tape to the "parts list" for the lamp box!

So everything was in place to start the engine! I switched the ignition on with my teeth (I had my fingers in my ears, just in case!) and the heater warning light came on for five seconds and clicked off nicely. However, the alternator light didn't come on! After a slight panic, I disconnected the lead that goes from the alternator "light" to the second heater relay (which shorts the shunt resistor) and the alternator light now works nicely too. I suspect the wise person would leave the heater relay off, but I might try a couple of diodes in the leads and see if that cures the problem. As there was no smoke coming off anything, the next step was to try starting the engine! Try was the operative word as, after ten seconds there was no sign of life, a second burst didn't fare any better. It was then I remembered that there was a tee shirt in the air intake! With that obstruction removed, I tried the starter again and the engine tried to fire, but the battery was too flat to have the desired result.

So it was out with the charger and I left it charging for about three hours while I had lunch and walked the dog. I went back and gave it another go and, although the battery wasn't fully charged, it started almost straight away. I stopped the engine almost as soon as I had it running as there isn't any water in it (no header tank on yet). So the Land Rover lives again - and I am somewhat relieved.

Re: A Landy is reborn

Great stuff, you're enjoying this and it shows in the high quality of your work, but about that: Land Rover themselves couldn't be arsed to make everything neat and tidy under the bonnet so if you're hoping to impress the marque aficionados with yours, you might want to leave some random wires lying around not going anywhere, then pour some used oil over everything in the engine bay, that should get it looking thoroughly authentic!

A few years ago, the Kitten Register was having quite a few failures with n/o/s brake cylinders, we were getting those particular ones from Speedy Spares. After the third failure - fortunately these things invariably let go when bleeding was attempted rather than in service - Speedy Spares started issuing new cylinder repair kits with their old stock brake parts as the cylinders themselves had been stored carefully so had perfect bore surfaces and sure enough, after we started fitting new rubbers to these things, not one single complaint came in from a register subscriber. The original seals in the n/o/s cylinders were barely identifiable in some cases and even the better examples had horrid black goo-fadge where should have been fresh, supple rubber. This phenomenon followed me into tape recorder repair work as capstan sleeves and idler tyres in older equipment are invariably similarly rotten.

Nowadays, we get brake parts elsewhere as Speedy ran out of the types we were ordering, so before we placed any orders with the new supplier, we negotiated for a fresh seal kit to be sent out with each cylinder sold. I'd sooner have that to do than buy a new cylinder made last week to a far lower quality than the old stock ones, it's a very inexpensive way to obtain peace of mind.

J

"Home is where you park it", so the saying goes. That may yet come true..

"Home is where you park it", so the saying goes. That may yet come true..

-

tractorman

- Posts: 1399

- Joined: Mon Feb 21, 2011 11:22 am

- Location: Wigton, Cumbria

Re: A Landy is reborn

I suspect the photos make the wiring look slightly better - though I do have high standards, so I'm never satisfied with my efforts! A Land Rover is one heck of a lot simpler to rewire than my model railway was (before I simplified it). Mind you, I was an Instrument & Control type and the sparkys hated our wiring methods as they were relatively sloppy!

I am glad to say that there are no signs of fresh brake fluid after our bleeding efforts, so I am fairly confident the unions are tight enough and hopeful that the new new master cylinder will cure the problem (and it will be easier to fit new seals to that than the dual circuit one if I need to do so!). I had intended to change that and alter the pipes today, but have been sidetracked - the Mormons have started competing with the Jehovah's Witnesses and are more persistent!! There are one or two "scrag ends" to sort in the engine compartment: the throttle linkage is yet another badly made bodge that sometimes locks the pedal closed! I also need to sort out the new air filter and connect the breather pipe to the induction pipe somehow. However, I suspect the air filter may need to be mounted on the inner wing, so that may delay the final fix.

I am glad to say that there are no signs of fresh brake fluid after our bleeding efforts, so I am fairly confident the unions are tight enough and hopeful that the new new master cylinder will cure the problem (and it will be easier to fit new seals to that than the dual circuit one if I need to do so!). I had intended to change that and alter the pipes today, but have been sidetracked - the Mormons have started competing with the Jehovah's Witnesses and are more persistent!! There are one or two "scrag ends" to sort in the engine compartment: the throttle linkage is yet another badly made bodge that sometimes locks the pedal closed! I also need to sort out the new air filter and connect the breather pipe to the induction pipe somehow. However, I suspect the air filter may need to be mounted on the inner wing, so that may delay the final fix.

Re: A Landy is reborn

Are you running a length of welding wire through your new loom so you can bend it to shape and have it stay there? I have seen that done a few times to make wiring looms look tidy.

Understeer: when you hit the wall with the front of the car.

Oversteer: when you hit the wall with the back of the car.

Horsepower: how fast you hit the wall.

Torque: how far you take the wall with you.

Oversteer: when you hit the wall with the back of the car.

Horsepower: how fast you hit the wall.

Torque: how far you take the wall with you.

Who is online

Users browsing this forum: No registered users and 9 guests