Its been a couple of weeks since I last posted and most of this time has been spent cleaning components and buying and waiting for new (plus of course Christmas). I have also had the crank reground and new shells sourced and finally have come to the more enjoyable part of the process where one can start to reassemble things. The only missing piece in the jigsaw is a new spin on filter adaptor to replace the old and now unobtainable disposable canister unit, which I have ordered from Peter Edney MG Spares, but has yet to materialise.

First came the installation of the engine onto a stand to make it easier to manipulate. I had never used one before, and had been a little wary due to the limited number of bolt fixings available and their small diameter. However, browsing the internet showed plenty of MG owners slinging their almost indentical XPAGs onto cantilever stands, and I decided to be brave. This gave me chance to clean out a couple of additional areas, and then assembly could start.

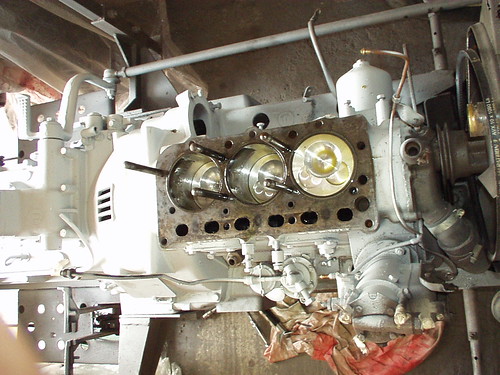

First came the fitting of the NOS Cords rings to the pistons. A good clean out of the grooves is essential and then they fit relatively easily. The lower two are spring steel scrapers assembled in four 'layers' and whilst long winded, in terms of getting each section the right way up, at least as spring steel components they are very forgiving, unlike traditional cast iron rings which are prone to breakage if not handled correctly. The upper two are cast, the very top one being stepped to avoid any wear ridge on the bore.

It was then necessary to do some glaze busting on the bores. There are lots of schools of thought about this. Some favour the old fashioned way with elbow grease and emery cloth, others a high tech honing tool which attaches to your power drill and is run up and down the bore to break the carbonised glaze that can stop your rings bedding in. Some say this is essential, others that it a myth and both sides of the argument can produce reams of testimony upholding their views. Given my desire to only do the job once, I decided to deglaze.....carefully.

Two things struck me. Firstly the power tool attachments seemed a touch savage to my eye and since the idea is to remove the lacquer on the surface of the metal rather than the metal itself , I was wary of an unfamilar tool that might do some real harm. Secondly there seems to be a lot of confusion between whether these attachments are for honing a raw rebored cylinder wall to give it a more appropriate surface texture, or whether they are for the gentler task of scraping off and texturing a layer of old carbonised oil.

I decided to go for emery cloth, and made up a hand tool out of foam pipe lagging with the abrasive taped around the outside. After adjusting the diameter by slicing layers out of the slot used to allow it to be slipped over a pipe. I got a suitable fit into the bore that allowed me to rotate and pull and push up and down each cylinder to abrade the glaze. A spray of WD40 before and a pull through with a rag afterwards, to remove the debris and all appears okay.

- Whats this? A simple home made tool for deglazing a bore without losing your knucles.

- DSCF1772comp.jpg (48.8 KiB) Viewed 1397 times

Next comes the refittng of the crank and bearings. The centre bearing on all of the X Series engines does not have a thrust washer as such, but has a white metalled shell bearing with a shoulder each side, which needs fitting when the crank is reground, since it too is oversized by the same amount as the journal has been ground down, if you follow what I mean.

The need to fit this was flagged up in an excellent article by Neil Cairns on a mechanically similar MG Y Type saloon on the Y Register website (see the following link)

http://www.mgccyregister.com/node/19058

Ian is a few steps ahead of me but the XPAG is so similar to my cooking XPJM, that it has been an excellent tutorial to follow, and a lot more explicit than the Workshop Manual, which is very Haynes like in its descriptions and totally fails to mention the need to 'fit' the centre main bearing at all. Ian also has a lot of hints on priming a newly assembled engine with oil, which will be invaluable before too long.

Pistons and crankshaft in tomorrow...but first I must buy a new piston ring compressor!